Oloa

-

Paipa fa'apipi'i ASTM A234 WPB & WPC e aofia ai tulilima, tee, ma mea fa'aitiitia

O lenei fa'amatalaga e aofia ai u'amea kaponi ma u'amea fa'a'au'au e leai ni so'oga ma ua fa'apipi'i. O nei mea fa'apipi'i e fa'aaogaina i paipa mamafa ma le gaosiga o ipu mamafa mo le tautua i le vevela feololo ma maualuga. O mea e fa'apipi'i ai e tatau ona aofia ai u'amea ua fasiotia, mea e fa'apipi'i ai, u'amea fa'apipi'i, ipu, mea e leai ni so'oga po'o ni oloa paipa fa'apipi'i fa'atasi ai ma le u'amea fa'apipi'i. E mafai ona faia galuega fa'apipi'i po'o le fa'atulagaina e ala i le tu'itu'i, oomi, tuiina, fa'aoso, fa'a'ofu, ta'avale, punou, fa'apipi'i fa'apipi'i, masini, po'o le tu'ufa'atasia o nei galuega e lua pe sili atu. E tatau ona fa'aogaina le faiga o le fausiaina ina ia le maua ai ni fa'aletonu matuia i mea fa'apipi'i. O mea fa'apipi'i, a uma ona fa'apipi'i i se vevela maualuga, e tatau ona fa'amālūlūina i se vevela i lalo ifo o le tulaga taua i lalo o tulaga talafeagai e puipuia ai fa'aletonu matuia e mafua mai i le vave tele o le fa'amālūlūina, ae e le sili atu le vave nai lo le fua fa'amālūlūina i le ea to'afilemu. O mea fa'apipi'i e tatau ona faia i le suega o le mamafa, suega o le ma'a'a, ma suega o le hydrostatic.

-

Paipa U'amea Kaponi e Le'i Fa'afefiloi ASTM A106 Gr.B

O lenei fa'amatalaga e aofia ai paipa u'amea kaponi e leai ni so'oga mo le tautua i le vevela maualuga i le NPS 1 i le NPS 48, fa'atasi ai ma le mafiafia masani o le puipui e pei ona tu'uina atu i le ASME B 36.10M. O paipa o lo'o oka i lalo o lenei fa'amatalaga e tatau ona talafeagai mo le punou, flanging, ma galuega fa'apena, ma mo le fa'avevela.

O matou o le Cangzhou Spiral Steel Pipes group co.ltd e iai a matou paipa masani mai le OD 1 inisi i le 16 inisi mo le tusa ma le 5000 Mt, e maua mai le TPCO, Fengbao Steel, Baoutou steel ma isi. I le taimi nei, e mafai ona matou tuʻuina atu paipa e leai ni faʻalavelave faʻalauteleina mo le lautele i fafo e oʻo atu i le 1200mm.

-

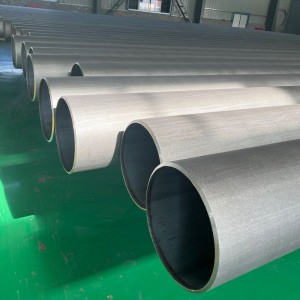

Paipa Uamea Fa'a'au'au Seamless ASME SA335 GRADE P11, P12, P22, P91, P92

E tele a matou paipa u'amea fa'a'ofuofu o lo'o iai, e amata mai i le 2 inisi i le 24 inisi, o ituaiga e pei o le P9, P11 ma isi e fa'aaoga mo le fa'avevela o le ogaumu vevela maualuga, economizer, header, superheater, reheater ma mo le alamanuia petrochemical ma isi. Fa'atino ia fa'amatalaga talafeagai e pei o le GB3087, GB/T 5310, DIN17175, EN10216, ASME SA-106M, ASME SA192M, ASME SA209M, ASME SA-210M, ASME SA-213M, ASME SA-335M, JIS G 3456, JIS G 3461, JIS G 3462 ma isi mea fa'apena.

-

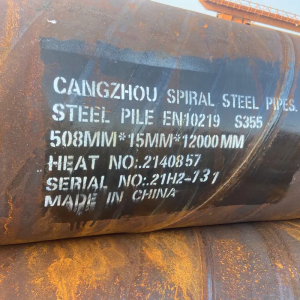

Paipa U'amea Fa'asusu i le Fa'asusuga Fa'asolosolo EN10219 Paipa U'amea SSAW

O lenei vaega o lenei Tulaga Faatonuina a Europa o loʻo faʻamaoti mai ai tuutuuga faʻapitoa mo le tuʻuina atu o vaega faʻapipiʻi ua faʻapipiʻiina malūlū, vaega gaogao o foliga faataamilo, sikuea poʻo le faatafafā ma e faʻaoga i vaega gaogao faʻapipiʻi ua faʻapipiʻiina malūlū e aunoa ma se togafitiga faʻavevela mulimuli ane.

E tu'uina atu e le Cangzhou Spiral Steel Pipes Group Co., Ltd ni paipa u'amea e fai i ni vaega gaogao o ni foliga lapotopoto mo le fausaga.

-

Paipa u'amea kaponi fa'a-helical-seam ASTM A139 Vasega A, B, C

O lenei fa'amatalaga e aofia ai vaega e lima o paipa u'amea ua fa'apipi'iina i le helical-seam ua fa'apipi'iina i le eletise (arc). O le paipa ua fa'amoemoe mo le fa'asalalauina o le vai, kesi po'o le ausa.

Faatasi ai ma laina gaosiga e 13 o paipa u'amea fa'asolosolo, e mafai e le Cangzhou Spiral Steel pipes group Co., Ltd. ona gaosia paipa u'amea fa'asolosolo ma le lautele i fafo mai le 219mm i le 3500mm ma le mafiafia o puipui e o'o atu i le 25.4mm.

-

Paipa Fa'apipi'i S355 J0 mo le Fa'atau

O lenei vaega o lenei Tulaga Faatonuina a Europa o loʻo faʻamaoti mai ai tuutuuga faʻapitoa mo le tuʻuina atu o vaega faʻapipiʻi ua faʻapipiʻiina malūlū, vaega gaogao o foliga faataamilo, sikuea poʻo le faatafafā ma e faʻaoga i vaega gaogao faʻapipiʻi ua faʻapipiʻiina malūlū e aunoa ma se togafitiga faʻavevela mulimuli ane.

E tu'uina atu e le Cangzhou Spiral Steel Pipes Group Co., Ltd ni paipa u'amea e fai i ni vaega gaogao o ni foliga lapotopoto mo le fausaga.

-

Paipa Fa'apipi'i e leai se Suia o le Laina SSAW X52

O matou o le Cangzhou Spiral Steel Pipes group co.ltd e iai a matou paipa masani mai le OD 1 inisi i le 16 inisi mo le tusa ma le 5000 Mt, e maua mai le TPCO, Fengbao Steel, Baoutou steel ma isi. I le taimi nei, e mafai ona matou tuʻuina atu paipa e leai ni faʻalavelave faʻalauteleina mo le lautele i fafo e oʻo atu i le 1200mm.

-

Fa'amatalaga API 5L 46th Edition mo le Va'aiga o Paipa Laina

Ua fa'amaoti mai ai le gaosiga o ni vaega oloa se lua (PSL1 ma le PSL2) o paipa u'amea e leai ni so'oga ma ua fa'apipi'iina mo le fa'aaogaina o se paipa i le felauaiga o le suau'u ma le kesi masani. Mo le fa'aaogaina o meafaitino i se talosaga tautua Sour taga'i i le Annex H ma mo talosaga tautua i fafo taga'i i le Annex J o le API5L 45th.

-

Ufiufi i fafo 3LPE DIN 30670 Ufiufi i totonu FBE

O lenei tulaga faʻatonuina o loʻo faʻamaoti mai ai manaʻoga mo ufiufi polyethylene extruded e tolu-vaega ma ufiufi polyethylene sintered e tasi pe tele-vaega mo le puipuiga mai le 'ele o paipa uʻamea ma mea faʻapipiʻi.

-

Paipa U'amea Fa'apipi'i Fa'alava ASTM A252 Vasega 1 2 3

O lenei fa'amatalaga e aofia ai faaputuga paipa u'amea e fai i puipui fa'apitoa o le foliga fa'ata'amilomilo ma e fa'atatau i faaputuga paipa lea e galue ai le silini u'amea e fai ma vaega tumau e amoina avega, pe o se atigi e fausia ai faaputuga sima ua faia i le nofoaga.

E sapalai e le Cangzhou Spiral Steel pipes group co.,ltd paipa uelo mo galuega fa'apipi'i pou i le lautele mai le 219mm i le 3500mm, ma le umi e tasi e o'o atu i le 35 mita.

-

Ufiufi Epoxy Fa'apipi'i Fa'atasi Awwa C213 Tulaga Masani

Ufiufi ma Linings Epoxy ua Fa'apipi'i Fa'atasi mo Paipa Vai U'amea ma Mea Fa'apipi'i

O se tulaga fa'atonuina lea a le American Water Works Association (AWWA). O vali FBE e fa'aaogaina tele i paipa vai u'amea ma mea fa'apipi'i, mo se fa'ata'ita'iga o paipa SSAW, paipa ERW, paipa LSAW, paipa seamless, tulilima, tees, reducers ma isi mo le fa'amoemoe e puipuia ai mai le 'ele.

O ufiufi epoxy ua fa'apipi'iina i le fusion o ni ufiufi thermosetting e tasi le vaega o le pauta mago, pe a fa'agaoioia i le vevela, e maua ai se tali fa'akemikolo i luga o le paipa u'amea a'o fa'atumauina pea le lelei o ona uiga. Talu mai le 1960, ua fa'alauteleina le fa'aoga i paipa tetele e pei o ufiufi i totonu ma fafo mo le kesi, suau'u, vai ma otaota.